Improving Factory Safety Through Machine Learning

SOFTWARE DEVELOPMENT

The Challenge

A large manufacturing client based in Iowa came to Shift wanting to create a computer vision prototype to track when large metal discs move through its furnaces and are ready to be transferred to a cooling stage. Today the transfer happens manually with a worker waiting for the discs to be ready and moving them over to the production stage.

The goal was to enable the use of robotics and increase safety for team members by removing

the need to have a team member work near the hot furnace.

OUR APPROACH

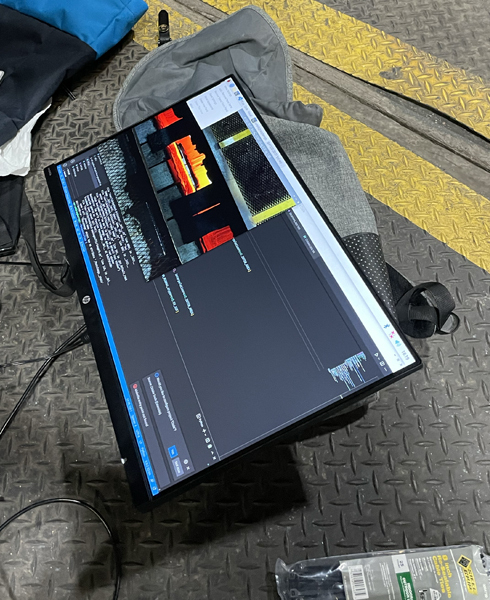

Shift leveraged an off-the-shelf camera and a computer device to capture video input of the furnace and detect when discs have moved completely through the process. The team used a custom machine learning workflow to design, train, and deploy a TensorFlow lite model.

The Solution

Shift developed a proof of concept using a Raspberry Pi 4 and a Raspberry Pi high-quality camera, which successfully detected discs coming near the end of the furnace and was able to withstand the high heat of the furnace. Shift took a visit to our client's factory to take pictures with the camera equipment in order to train the model.

Once Shift was able to validate the concept, we gathered and labeled the images of the blades traveling through the machine, we used these labeled images to train a TensorFlow lite image segmentation model, and we deployed the model to Raspberry Pi 4 for on-device processing with a web output of the image processing for remote monitoring . The proof of concept was designed to send a signal to a robot when a disc moves into the completed zone, once our client chose to have a robot in place.

For now, Shift set up a small web app for our client's employees to track the images and progress of further training the model.

TECHNOLOGIES

Python

AI

Machine Learning

Tensorflow

Computer Vision

SERVICES

Software Development

OUTCOME

While the proof of concept was successful in detecting discs near the

end of the furnace, the team identified that more tweaks were needed before it could be

scaled up to a production-ready tool. Despite this, the proof of concept

demonstrated Shift's expertise in developing cutting-edge computer vision

solutions for clients in need of automation and safety improvements.

BIG IDEA?

WE CAN HELP BRING

IT TO LIFE

BETTERING THE EYE CARE

EXPERIENCE WITH MACHINE

LEARNING